Angle Grinder Commutator For Power Tools

This Angle Grinder Commutator For Power Tools is suitable for electric tools, household appliances, automobiles, motorcycles and other fields.. NIDE is engaged in the design, development, and production of slot, hook, and planar commutators (collectors) for DC motors and universal motors. And can provide various types of motor commutators according to customer needs. We have a complete quality assurance system and an advanced enterprise management system.The following is an introduction to Angle Grinder Commutator For Power Tools, I hope to help you better understand it.

Model:NDPJ-HXQ-640A

Send Inquiry

Angle Grinder Commutator For Power Tools

The commutator fits angle grinder power tool motors.

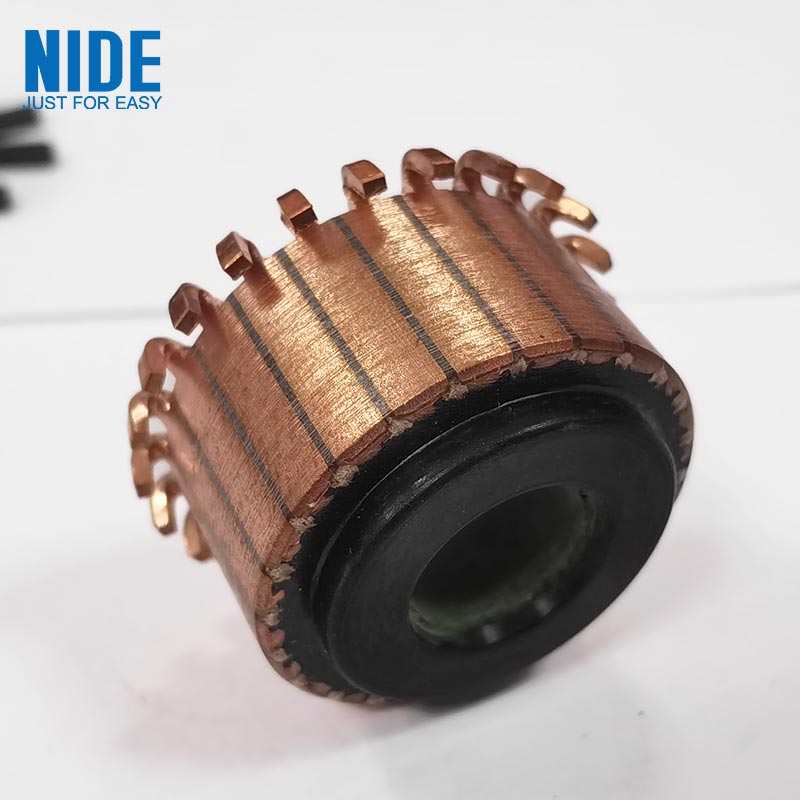

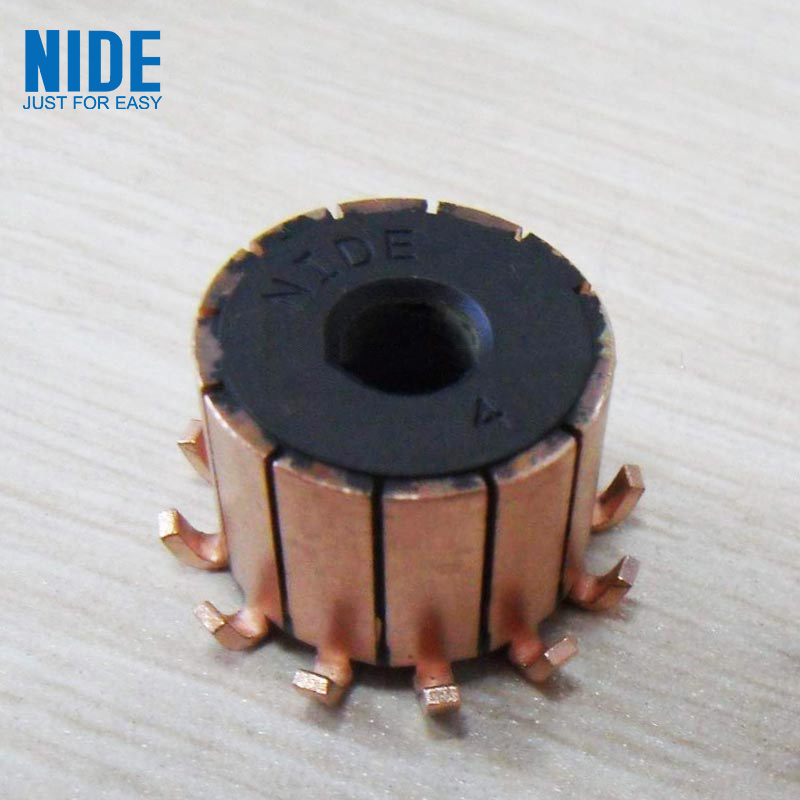

The angle grinder commutator is widely used in household motors and power tools. The basic structure of the commutator is: including commutator copper pieces evenly distributed on the outer circumference of the commutator body. The commutator bodies are injection-molded together, and the commutator copper sheets are provided with fins which are implanted into the commutator body and firmly combined with the commutator body.

Angle grinder commutator parameters

Product Name: Angle grinder commutator

Material: Copper

Type: Hook Commutator

Hole diameter: 8.4mm

Outer diameter: 25mm

Height: 16mm

Slices : 24P

MOQ: 10000P

Angle grinder commutator display

Angle grinder commutator failure and maintenance

The angle grinder uses a series motor, which is characterized by two carbon brushes and a commutator on the rotor. The most commonly burned parts of this type of motor are the commutator and rotor winding ends. If the commutator is burnt, it is generally because the carbon brush pressure is not enough. When the motor is working, if the current continues to be large, the carbon brushes will wear out quickly. After a long time, the carbon brushes will become shorter, the pressure will become smaller, and the contact resistance will be very large. At this time, the surface of the commutator will heat up very seriously.

If there is a ring fire or a large spark on the commutator of the angle grinder, it is necessary to replace the carbon brushes, remove the sundries, make the surface of the commutator smooth or replace the commutator with a new one.