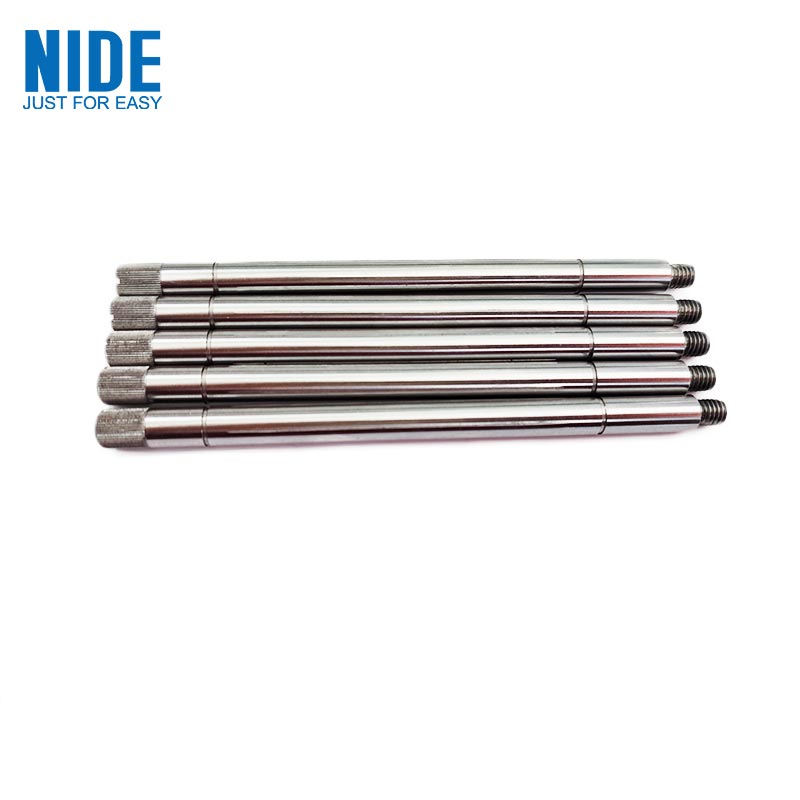

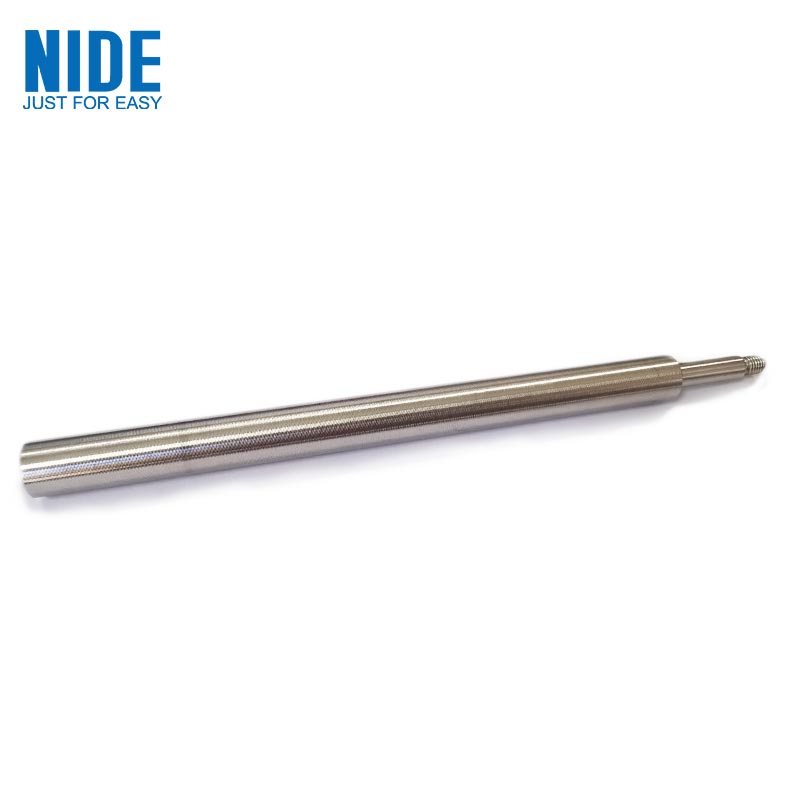

Food Mixer Motor Shafts Linear Shaft

NIDE is specializes in supplying various types of Food Mixer Motor Shafts Linear Shaft, which can be processed and customized. The company has advanced equipment, and actively introduces advanced technology equipment and management mode from Japan and Germany. The products are widely used in home appliances, cameras, computers, communications, automobiles, mechanical instruments, micro motors and other precision industries, and have established a relatively complete sales channel. The products are not only sold well in China, but also exported to Hong Kong, Taiwan, Europe and North America.

Model:NDPJ-Z-10

Send Inquiry

Food Mixer Motor Shafts Linear Shaft

Our motor shafts have the characteristics of high strength, high precision requirements, good wear resistance, good corrosion resistance and good processing performance to ensure the performance and service life of the motor.

The manufacture of the mixer motor shaft needs to strictly control the requirements of materials, processing technology and quality to ensure that the quality and performance of the shaft meet the requirements of use. Generally consider the following aspects:

1. Material selection: The motor shaft is usually made of high-strength alloy steel or stainless steel. The choice of material needs to be determined according to factors such as the environment in which the mixer is used, the load, and the size of the shaft.

2. Shaft processing technology: The processing technology of the motor shaft usually includes multiple links such as turning, grinding, and drilling. These links need to strictly control the machining accuracy to ensure that the diameter, length, roundness and other dimensions of the shaft meet the requirements.

3. Surface treatment: In order to improve the surface quality and service life of the motor shaft, surface treatment is generally required. For example, sandblasting, polishing, electroplating and other methods can be used to treat the surface of the shaft.

4. Assembly and inspection: After the manufacture of the shaft is completed, assembly and inspection are also required. When assembling, attention should be paid to the positioning and fit of the shaft to ensure that the shaft can be installed correctly in the mixer. During the inspection, it is necessary to carry out inspections on dimensions, hardness, and axial runout to ensure that the quality of the shaft meets the requirements.

Product Parameter (Specification)

|

Stainless steel |

C |

St |

Mn |

P |

S |

Ni |

Cr |

Mo |

Cu |

|

SUS303 |

≤0.15 |

≤1 |

≤2 |

≤0.2 |

≥0.15 |

8~10 |

17~19 |

≤0.6 |

|

|

SUS303CU |

≤0.08 |

≤1 |

≤2.5 |

≤0.15 |

≥0.1 |

6~10 |

17~19 |

≤0.6 |

2.5~4 |

|

SUS304 |

≤0.08 |

≤1 |

≤2 |

≤0.04 |

≤0.03 |

8~10.5 |

18~20 |

||

|

SUS420J2 |

0.26~0.40 |

≤1 |

≤1 |

≤0.04 |

≤0.03 |

<0.6 |

12~14 |

||

|

SUS420F |

0.26~0.40 |

>0.15 |

≤1.25 |

≤0.06 |

≥0.15 |

<0.6 |

12~14 |

Product Details