Segmented Commutator For DC Motor

Send Inquiry

Segmented Commutator for DC Motor

1.Product Introduction

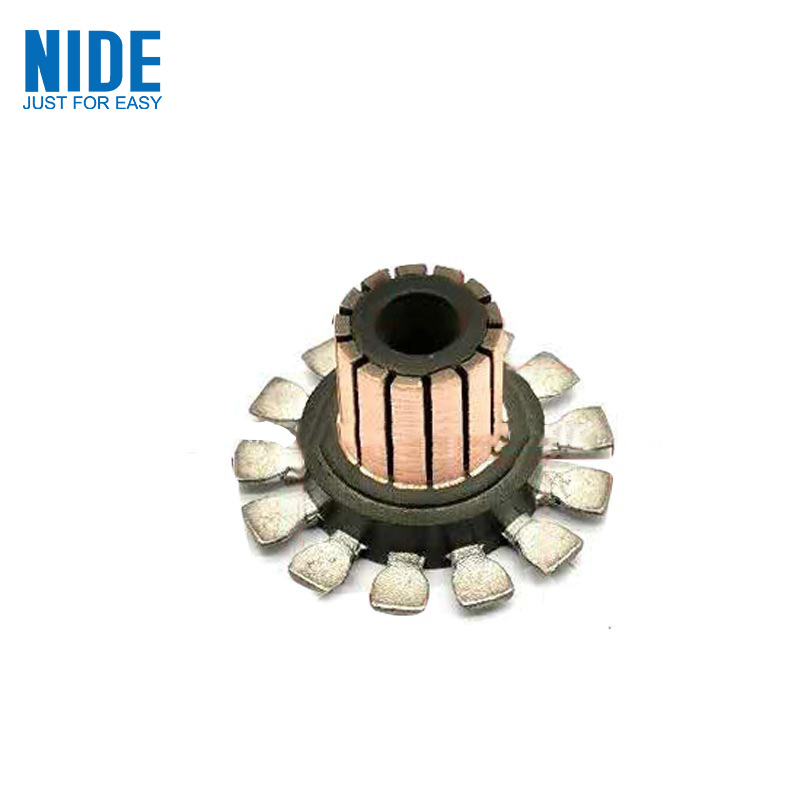

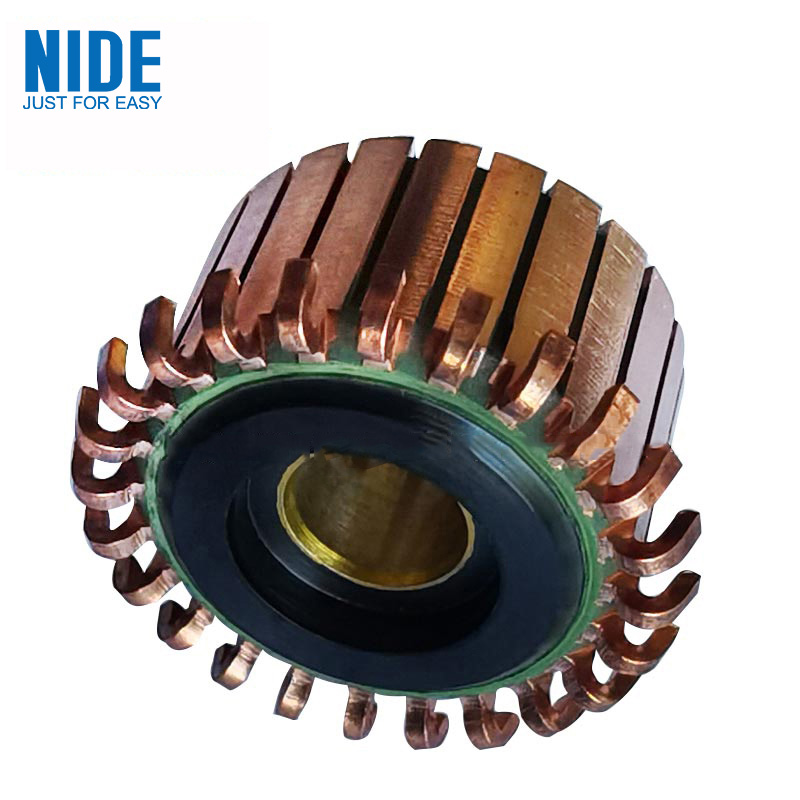

The Segmented Commutator for DC Motor adopts the method that the body is a flat head and wraps the end face of the pole piece to increase the strength of the combination of the pole piece and the body. The wrapping method is used to ensure that the pressure and temperature during welding do not deform the pole piece, and the injection mold is used The design of the pole piece improves the installation position of the pole piece, that is, the main plane of the pole piece is higher than the body plane, and the circular dot pattern is densely distributed on the main plane of the pole piece to increase the contact area during welding and to buffer the pressure during spot welding.

2.Product Parameter (Specification)

|

Product name: |

13P segment coreless motor commutator |

|

Brand: |

NIDE |

|

Material: |

silver copper reinforcement |

|

Scope of application: |

Electric tools, medical equipment, beauty instruments, aviation, aerospace, model airplanes, portable instruments, etc. |

|

Size: |

customized |

3.Product Feature And Application

This Segmented Commutator for DC Motor is suitable for hollow cup motors. The advantage is that it does not affect the performance of the motor, but also can guarantee the process of the motor in the production process, and the commutator processing is more stable, and the design and processing of the mold can be more convenient and quick, which saves costs and improves the process.

4.Product Details

Our Segmented Commutator for DC Motor adopts a new design scheme. The technical problem to be solved is to provide a commutator for coreless motors that will not deform the metal pole piece, open the mouth and burn the plastic body during the welding process, and can increase the strength of the combination.