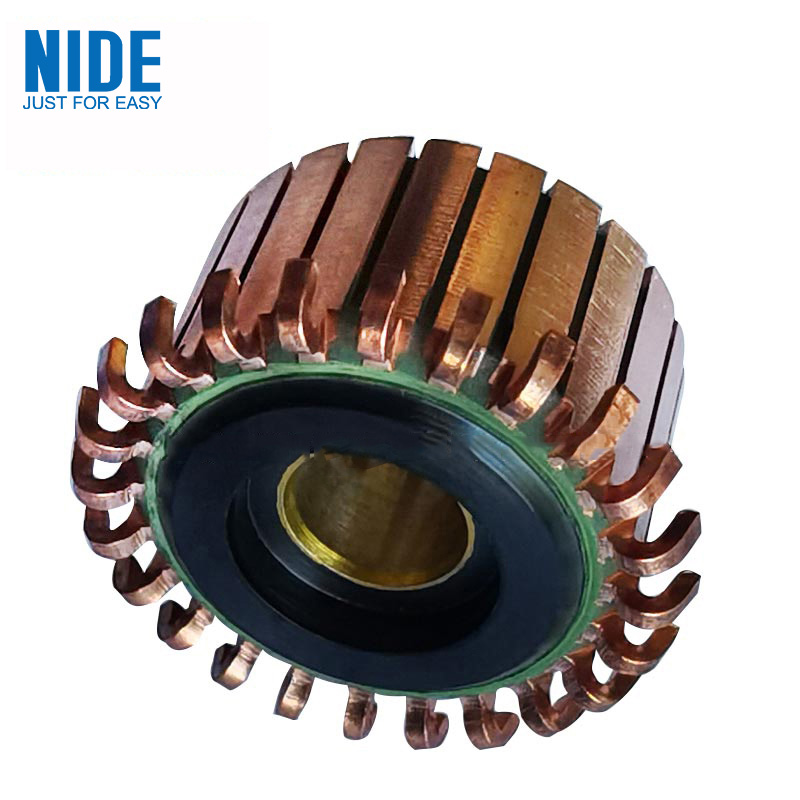

12P Hook Electrical Commutator For DC Motor

This 12P Hook Electrical Commutator For DC Motor is suitable for electric tools, household appliances, automobiles, motorcycles and other fields.. NIDE is engaged in the design, development, and production of slot, hook, and planar commutators (collectors) for DC motors and universal motors. And can provide various types of motor commutators according to customer needs. We have a complete quality assurance system and an advanced enterprise management system.The following is an introduction to 12P Hook Electrical Commutator For DC Motor, I hope to help you better understand it.

Model:NDPJ-HXQ-1009

Send Inquiry

12P Hook Electrical Commutator For DC Motor

The electrical motor commutator is widely used in a variety of electric tools, cars, motorcycles, household appliances and other electrical motors.

1. Commutator Parameters:

| Product name | Motor Commutator |

| Size | 8x23x20mm |

| Color | Copper tone |

| Teeth | 12 teeth |

| Material | Copper |

| Type | Hook Commutator |

| MOQ | 100000 |

2. Commutator Selection

When the motor needs to replace the whole commutator, it is necessary to detect the outer circle diameter of the commutator, the diameter of the inner hole, the length of the copper piece and the number of slots and other parameters, and then select the commutator with similar parameters to be absolutely equal, and try to choose the clip type commutator for replacement.

3. Commutator Picture

4. Commutator Replacement

a. Test whether the armature winding has short circuit and iron phenomenon, to be eliminated in time, so as not to leave behind trouble.

b. When the diameter of the inner hole of the commutator is small, it can be turned and enlarged on the lathe to reach the diameter of the inner hole required by the electric pivot; When the diameter of the inner hole is large, a bushing can be machined and pressed into the manhole.

c. The clip of the clip type commutator is generally a little longer, and the excess part can be cut off according to the need, and the opening is scraped clean for tin welding.

d. Slightly align the open slots of the commutator with the connecting wires of the armature winding one by one, and then slowly press the commutator onto the pivot until the position of the commutator meets the requirements.

e. Turn off the damaged commutator from the pivot shaft under the step of the wiring head or chisel the commutator after sawing a circle around the circle with a hacksaw under the step of the wiring head, then pull out and scrape the connecting wire head one by one with pliers for tin welding, and then remove the residual commutator part.